How it works?

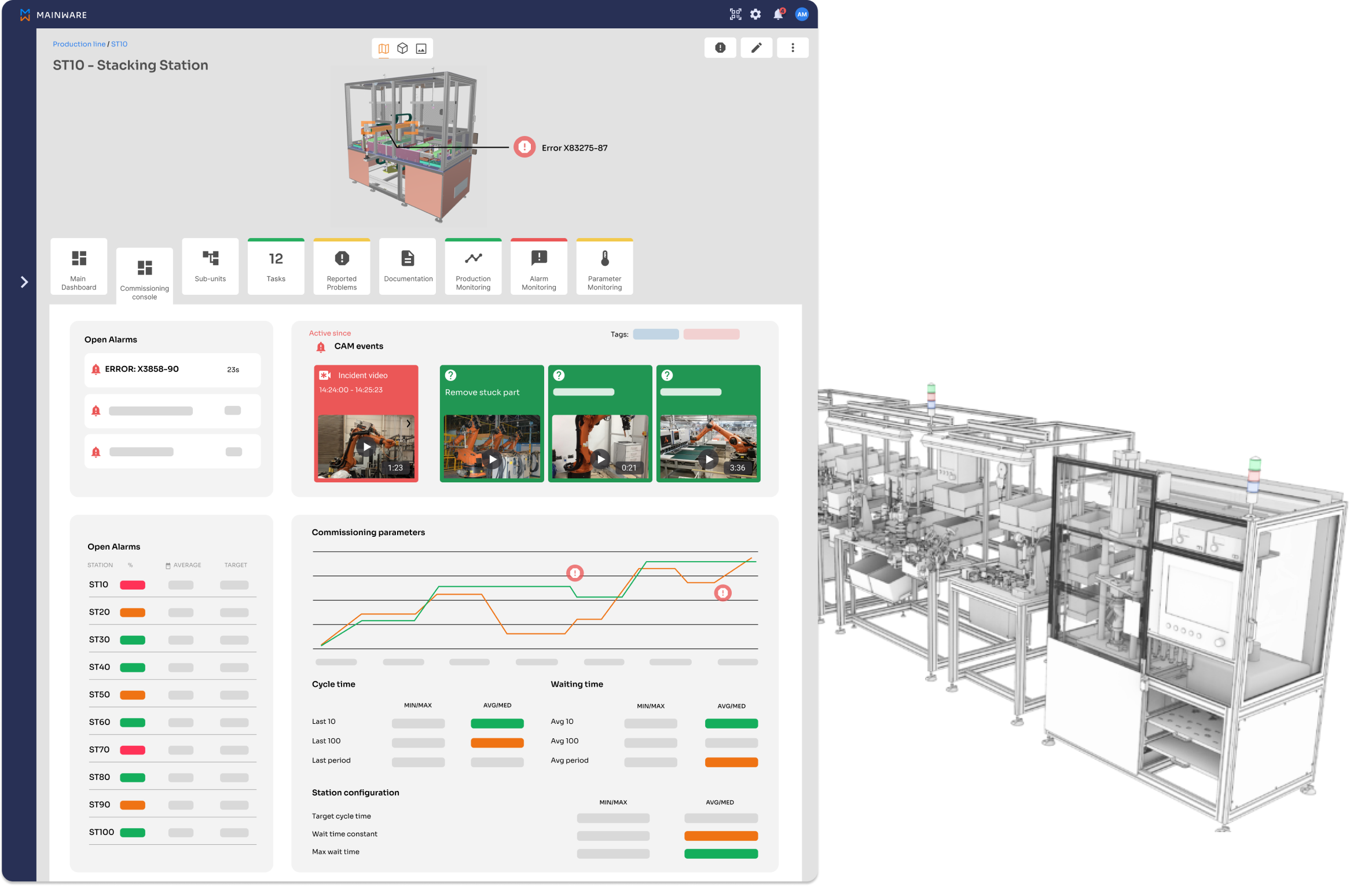

- Cloud.

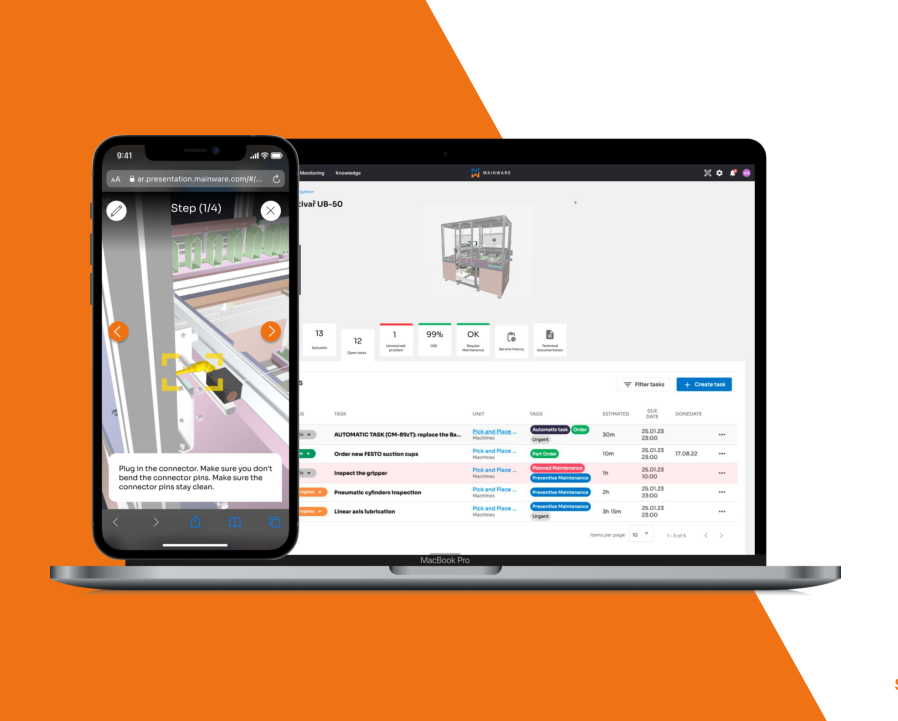

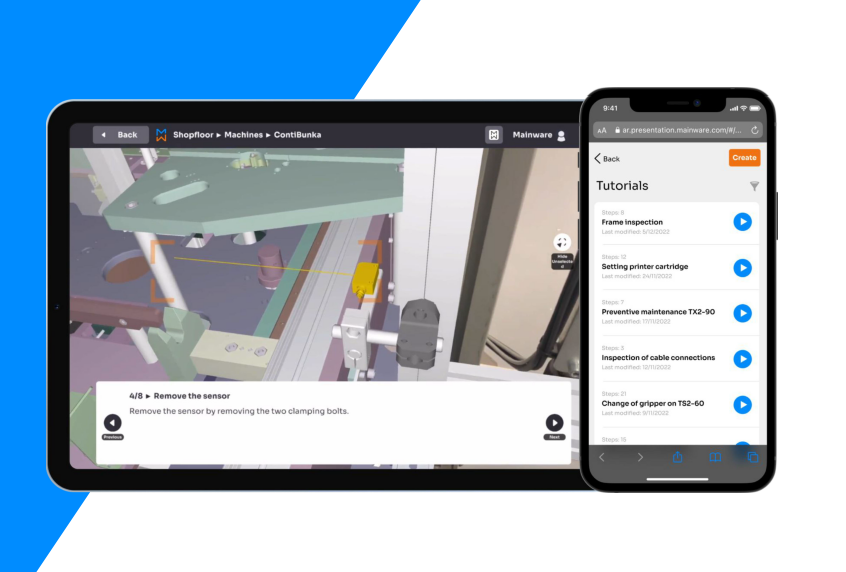

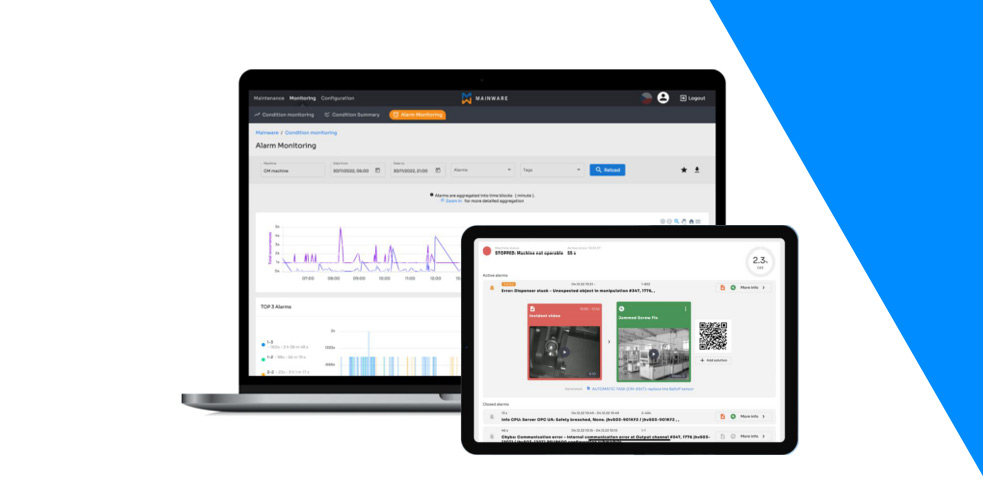

MAINWARE is a cloud based web application that runs in any browser, meaning it is not tied to an app store. - Multiplatforms.

MAINWARE is optimized for mobile devices so it makes work outside the office easier. Working on desktop is for more complex tasks. - SaaS.

MAINWARE is provided as a SaaS - Software as a Service. Monthly fee is set corresponding to how you use the system. - Customization.

The solution can be tailored to the needs of your company. Open API solution lets you integrate MAINWARE into your other systems.