Don't hesitate to contact us!

Any question is welcome

Mainware for machine builders

Your projects are getting

more complex and your

customers’ expectations

are rising!

Together with engineers from

the field of system integration,

MAINWARE has developed tools

to help you deliver complex

projects in a profitable way.

Start using a tool developed specifically for system integrators!

MAINWARE helps you analyze software and mechanical behavior of machines during

commissioning, handover and ramp-up phases of your projects. With these tools you

will debug your machines and solve problems at their root causes.

Be certain that your operation runs smoothly and is cost effective.

🕛 Identify problems in minutes

You will analyze alarms and video

footage to truly understand what is

happening on the machine.

🚀 Faster commissioning

You will debug and handover your projects faster by saving several weeks.

💶 Profitable projects

You will not waste time of your

technicians and avoid penalties

from late project delivery.

Start commissioning faster in a day.

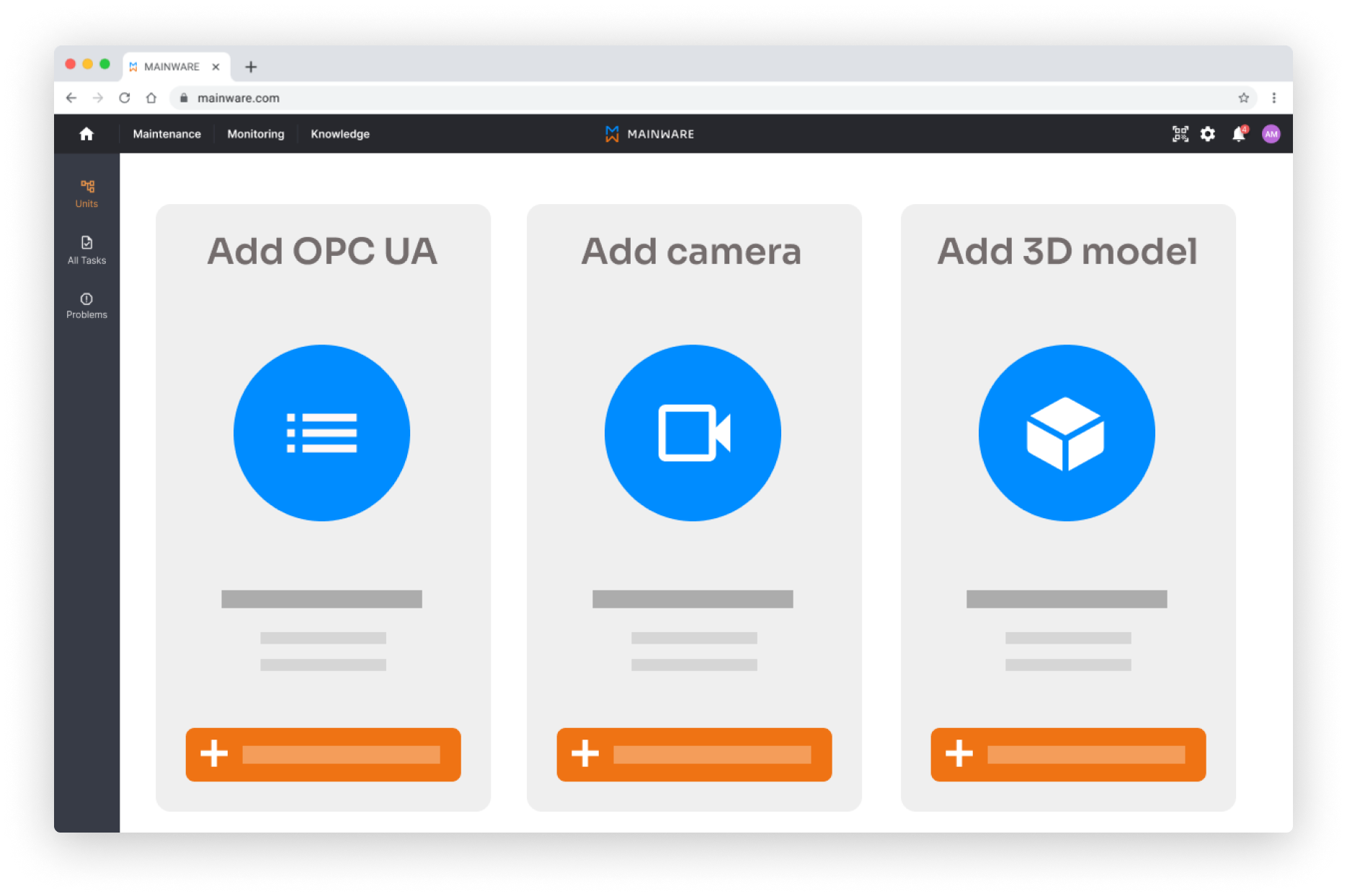

MAINWARE let’s you connect your machine for smart commissioning in few hours.

Start benefiting right away.

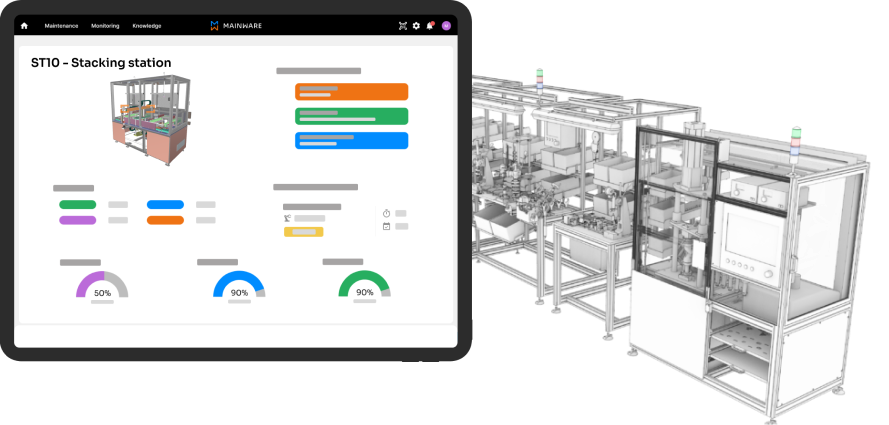

Prepare machine for commissioning

Upload 3D data of your project and connect machine’s OPC UA server to MAINWARE. Start smart commissioning within few hours. Connect cameras aiming at the most critical parts of the machine.

- Create your first MAINWARE project in minutes.

- Upload 3D models of stations in STEP up to 1 GB of size.

- Connect OPC UA over MAINWARE Gateway for secure communication.

- Connect multiple high-speed cameras. Use USB, ethernet or IP cameras.

Start collecting data

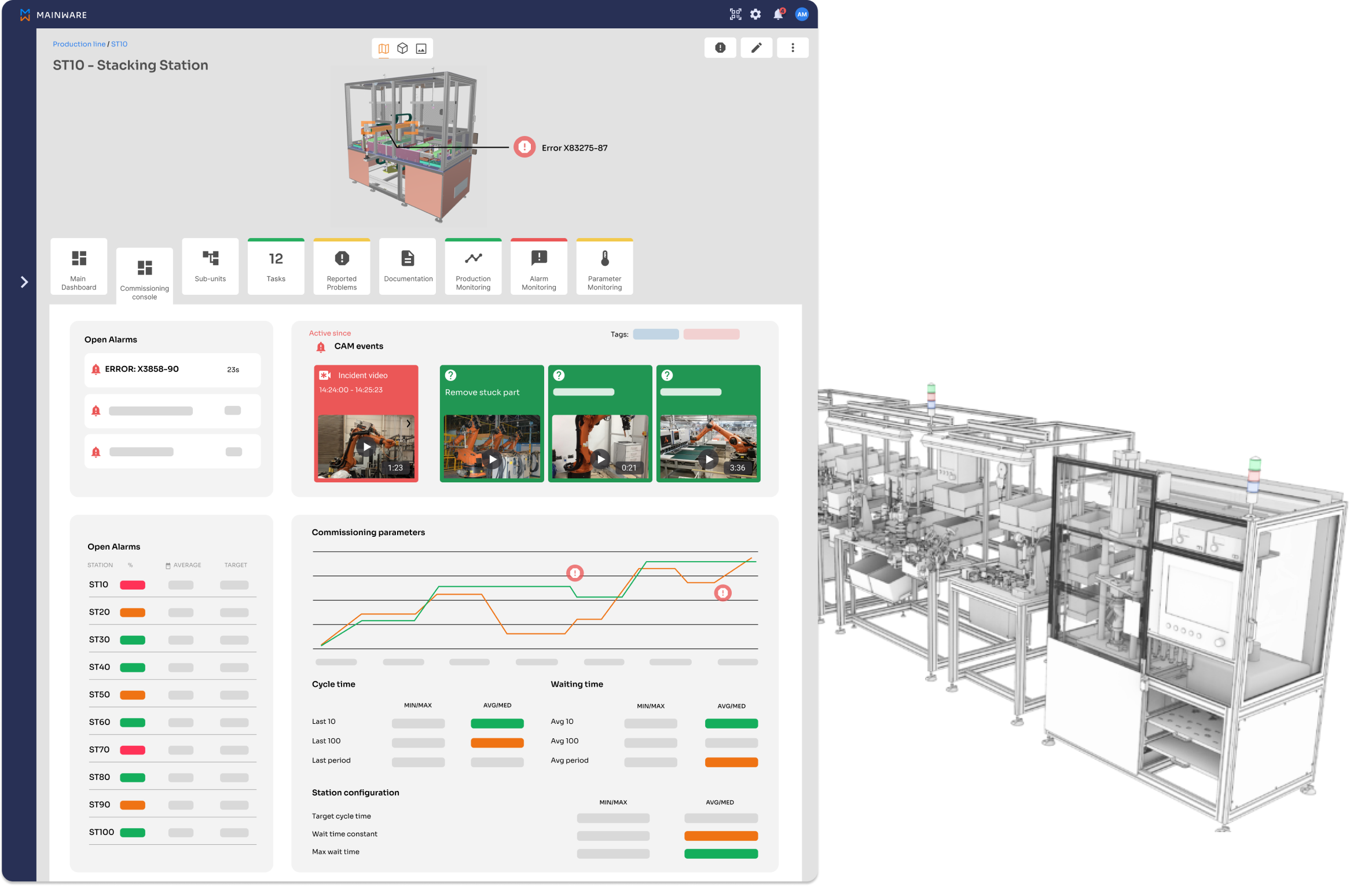

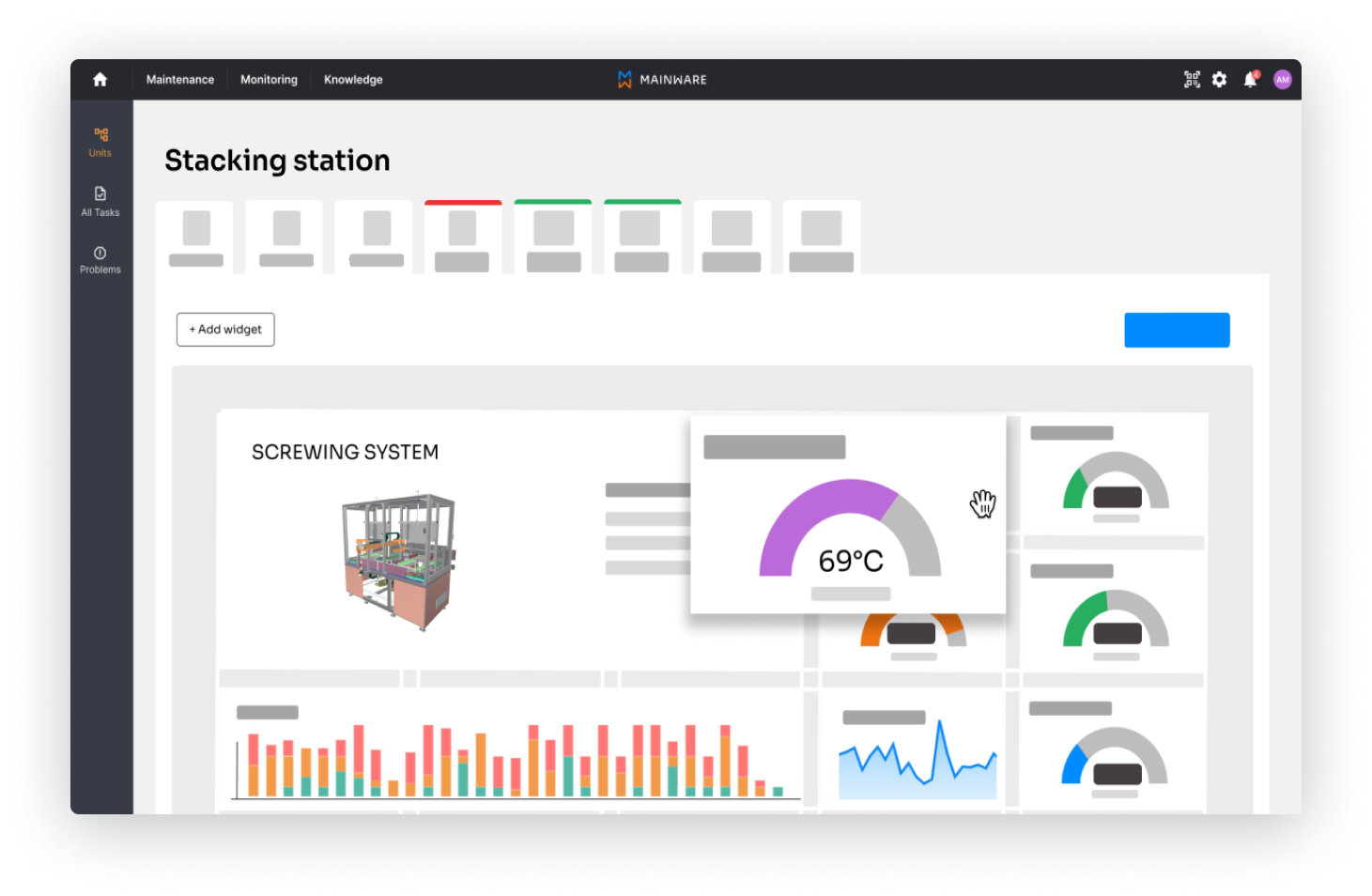

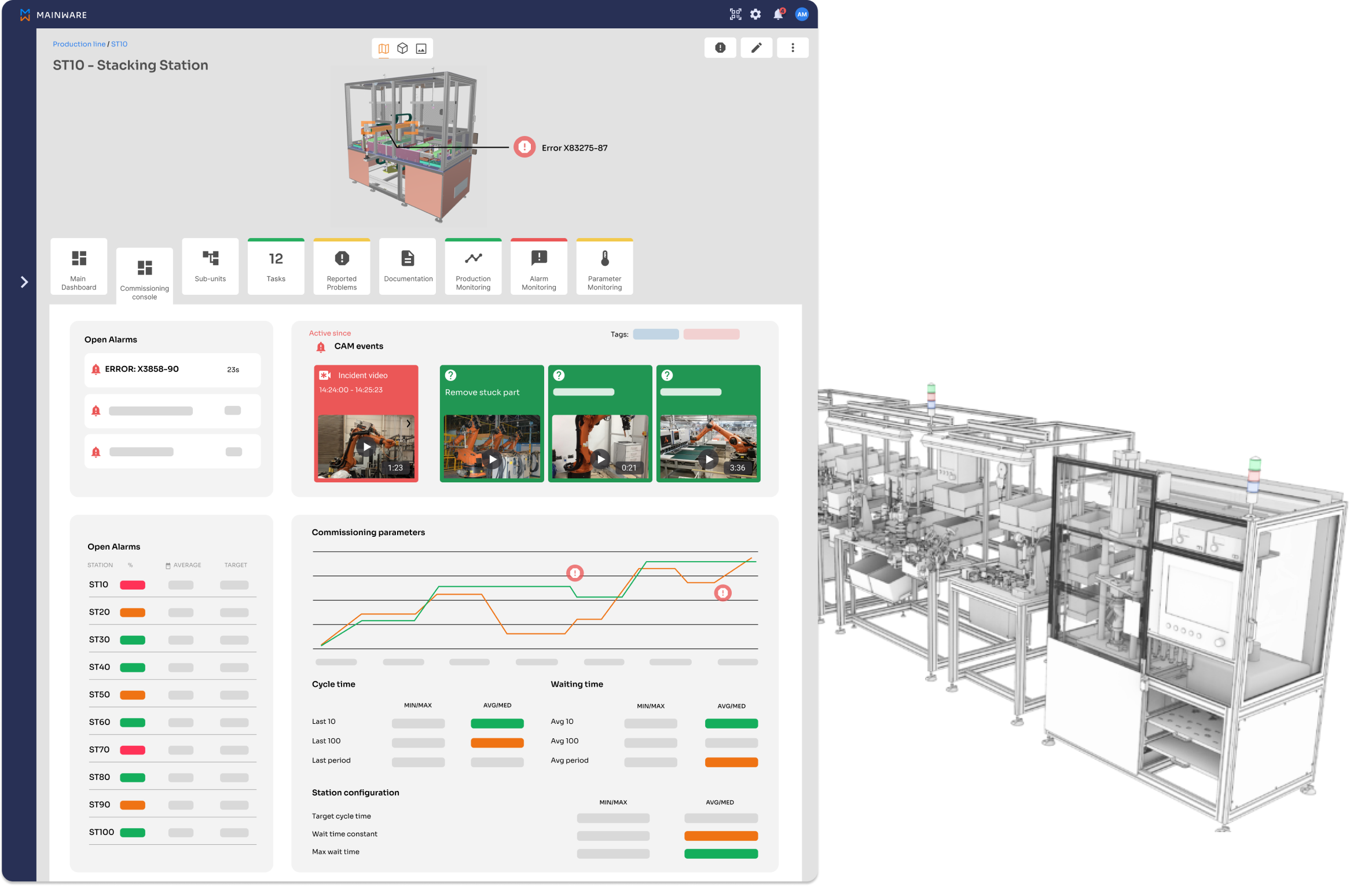

You immediately get all the alarms in MAINWARE. Sort them and start creating cause models to help you focus on the most important problems. Analyze footage from cameras to understand mechanical behaviour of the systems.

- Analyze each station independentily or the whole line.

- Check the occurances of alarms on a timeline. Sort them by frequency or duration, group them by tags or stations.

- Inspect cycle times to maximize machine’s output.

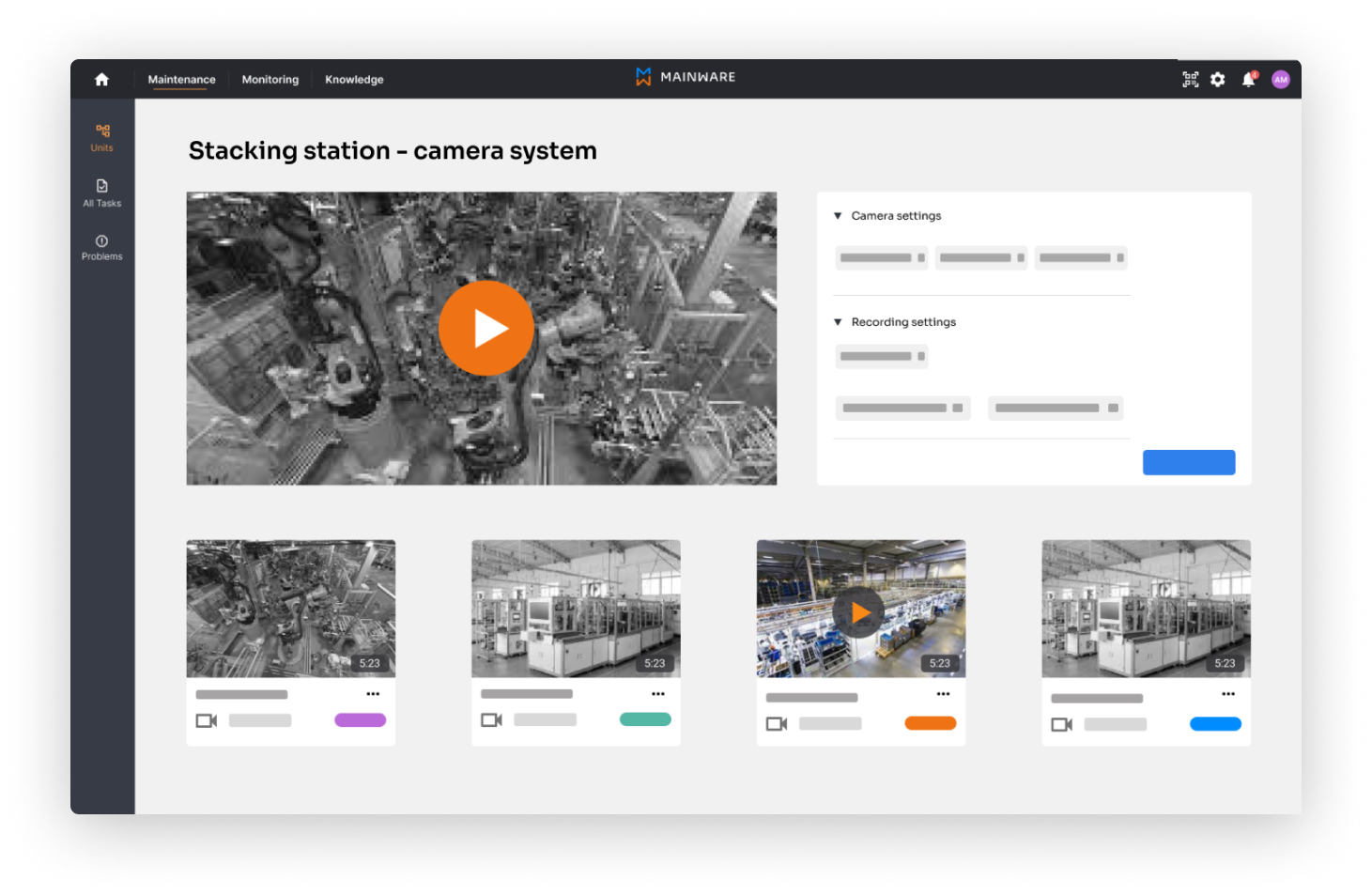

- Create triggers that will start recordings in multiple cameras.

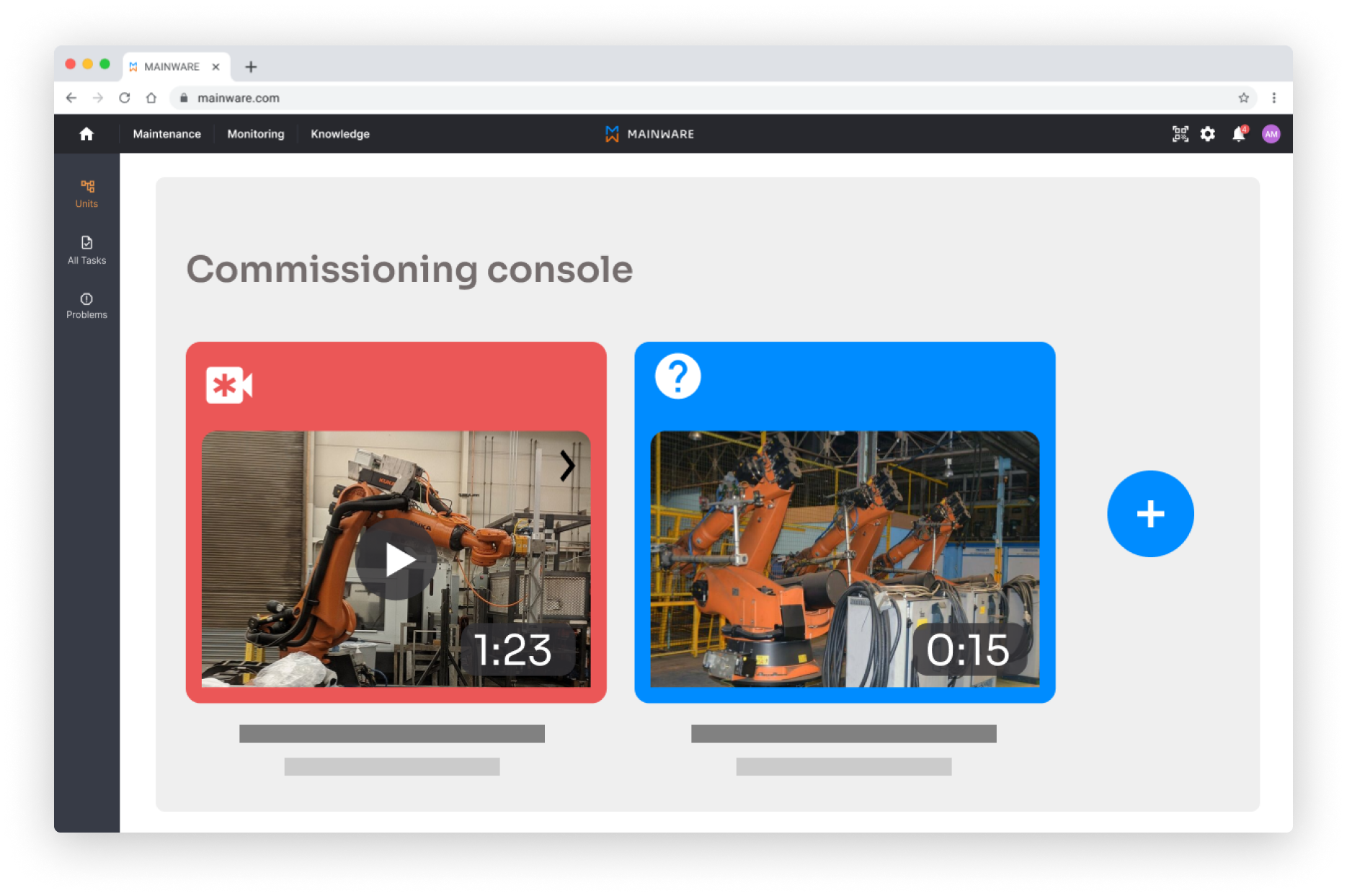

Solve problems and create solutions

Prioritize the list of incidents and start solving them. For each of these events you get a list of alarms together with video footage. This way you can solve both software and physical problems quickly.\

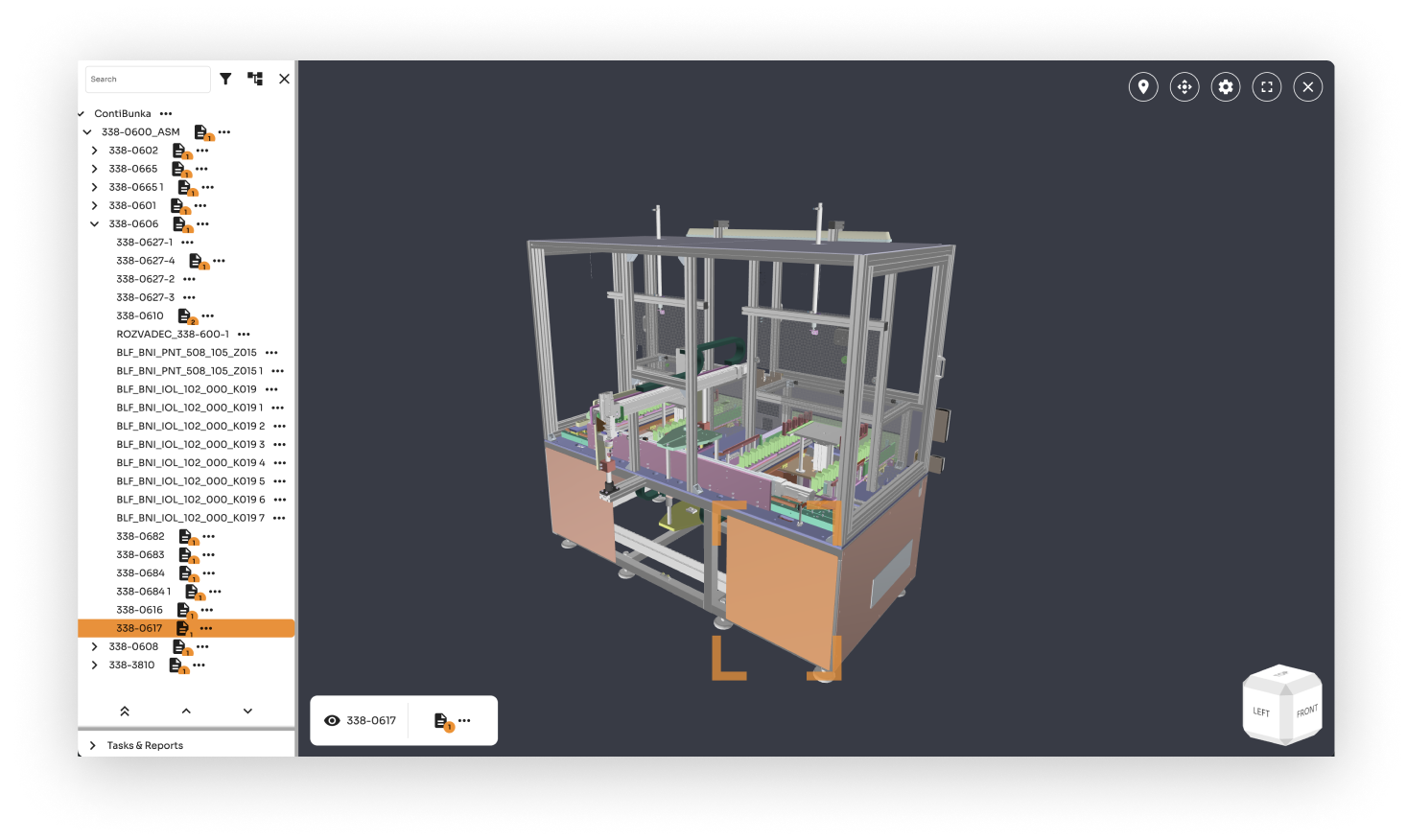

- Conduct a proper machine’s data analysis with commissioning tools directly in MAINWARE’s commissioning console.

- Localize electrical and pneumatic components faster with alarms connected to 3D model of the machine.

- Analyze high-speed footage frame by frame to understand mechanical events.

- Create annotated instructions with 3D, photo and video steps as a solution to incidents.

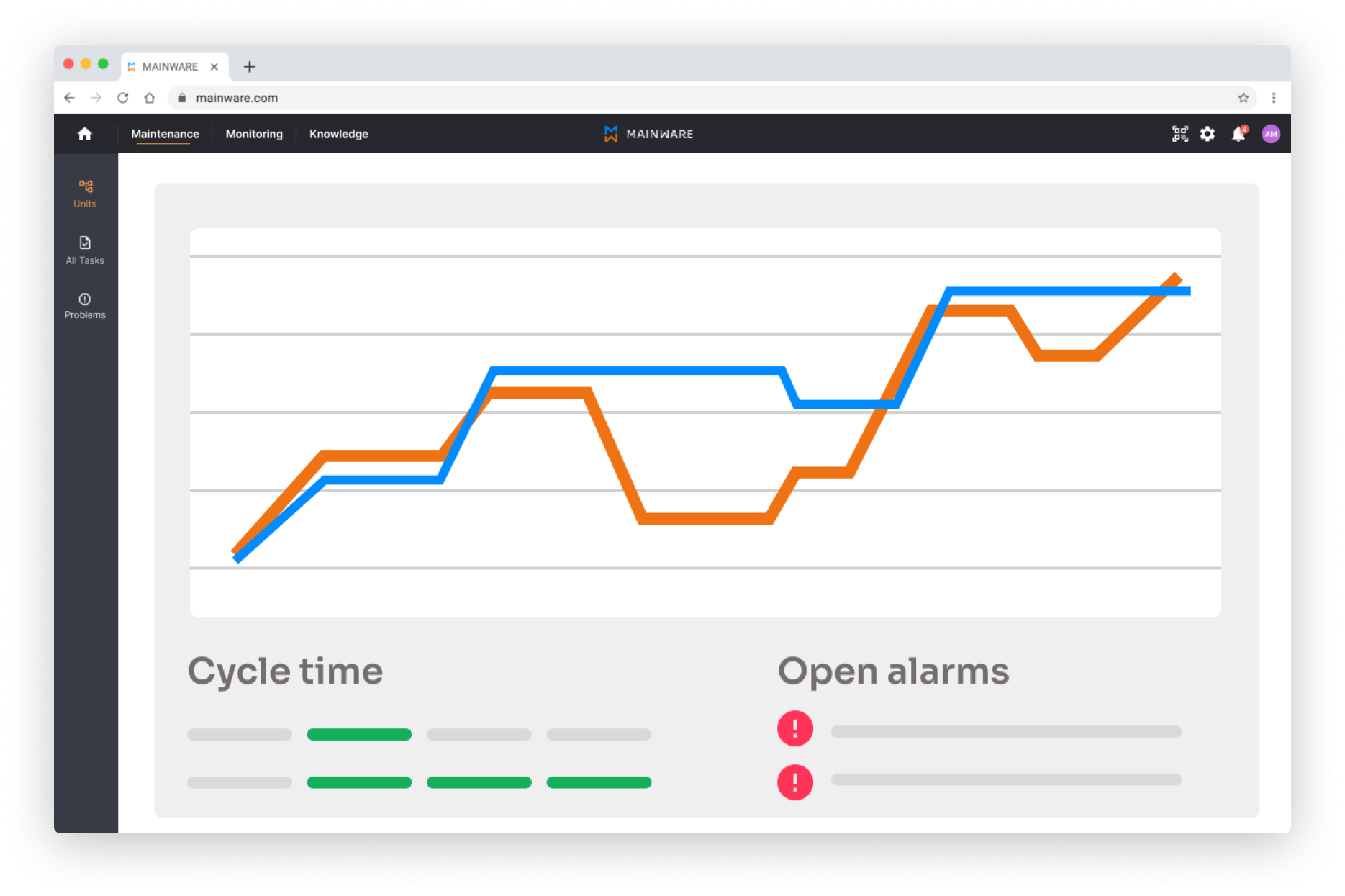

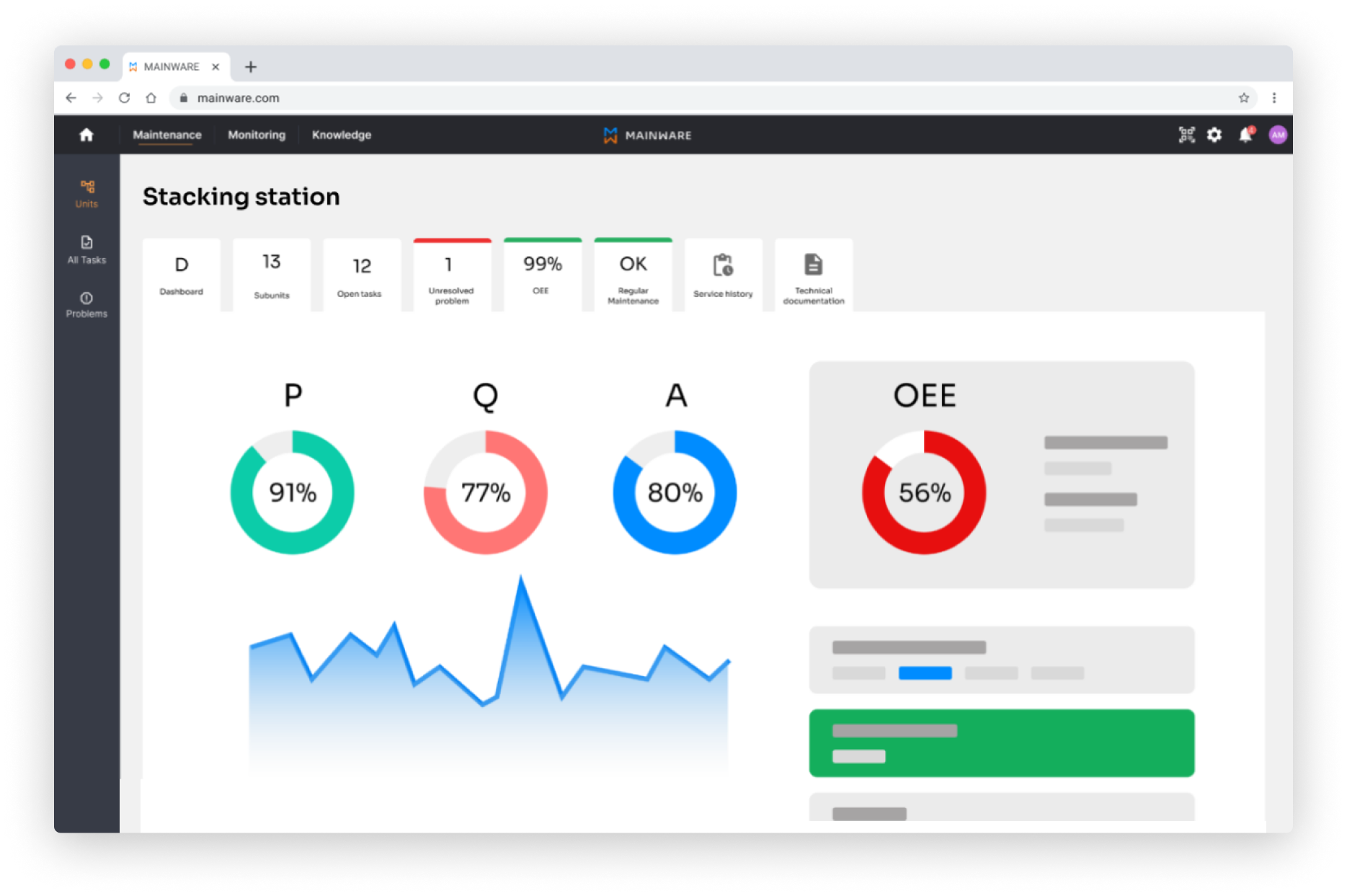

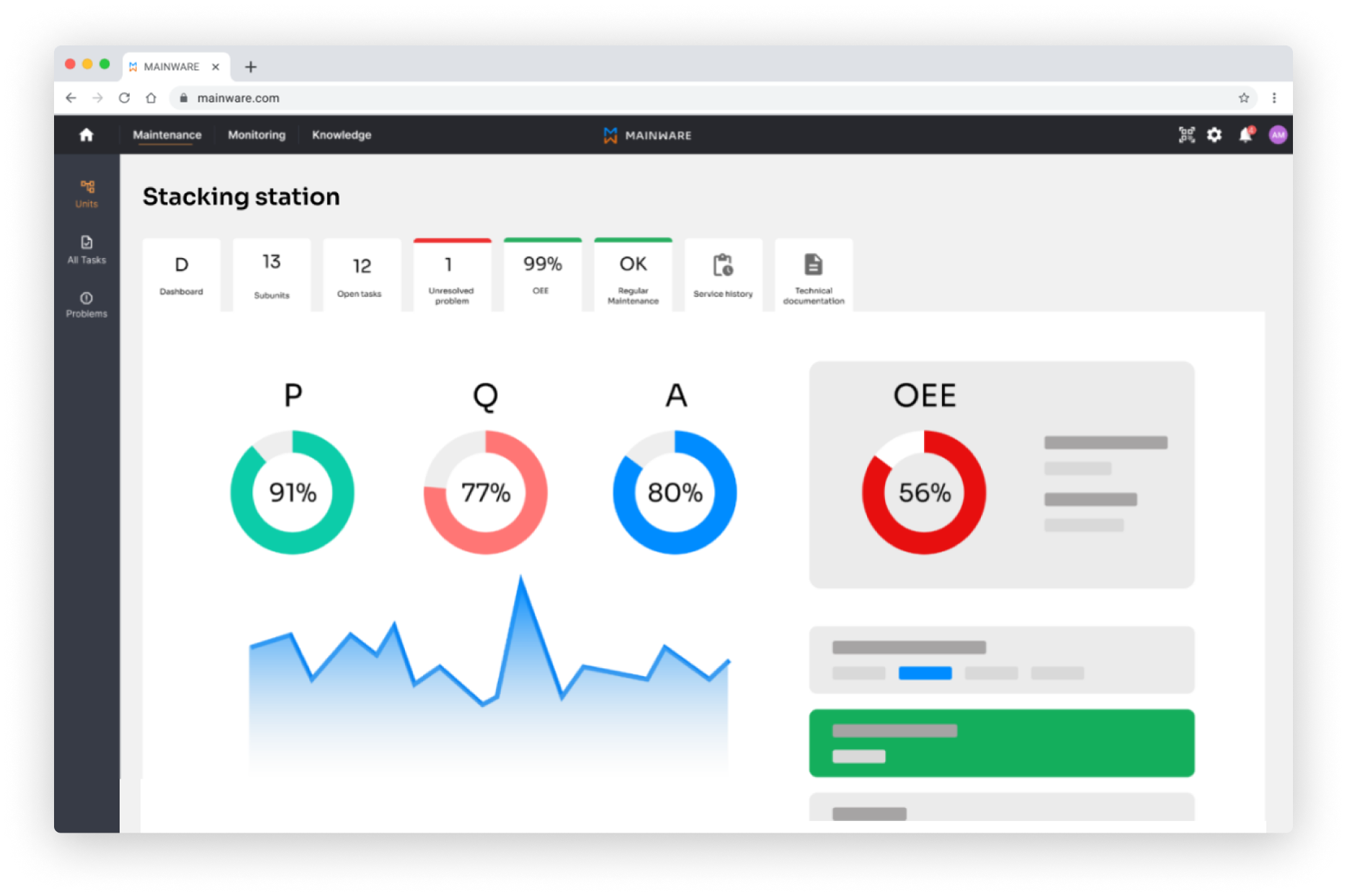

Machine handover based on data

Use data based approach to validate machine’s performance. The OEE analytics let’s you focus on the root causes of each downtime to reach required production. Create cause models and instructions that will enable the customer to operate the machine at high outputs

- Calculate OEE based on machine’s performance, quality and availability.

- Identify downtimes and categorize them by their root causes.

- Exclude external systems and customer’s operations toanalyze only the OEE of your machine.

- Enter planned production curves according to customer’s operations

Provide the tools and knowledge from

smart commissioning to your customer.

You have created loads of knowledge while commissioning the machine. This will help

your customer to operate the machine in a better way.

Sell this knowledge to your customer in a branded smart solution to generate new revenues.

Your commissioning

- Sorting of alarms for smart debuging.

- Creating instructions for solving problems.

- Using cameras for incidents analysis.

- OEE analytics for data based handover.

Their benefit

- More reliable machine with less problems

- Less dependency onintegrator’s support.

- Detailed monitoringof critical areas.

- OEE at steady level and focusing on key activities.

Key features for smart commissioning:

Learning from previous projects

Create knowledge database of your operations.Save notes, debugging procedures, 3D data,instructions or any documents that will help youcommission future projects faster.

3D documentation

Access detailed 3D model of the projects anytime and anywhere. Use searching and filtering tools to identify or locate components faster. Use MAINWARE Step-compare for a quick comparison between model versions.

High speed camera analysis

High speed camera analysis. Equip your machines with high speed cameras. Anytime something happens, cameras are triggered and short video is saved in MAINWARE for further analysis.

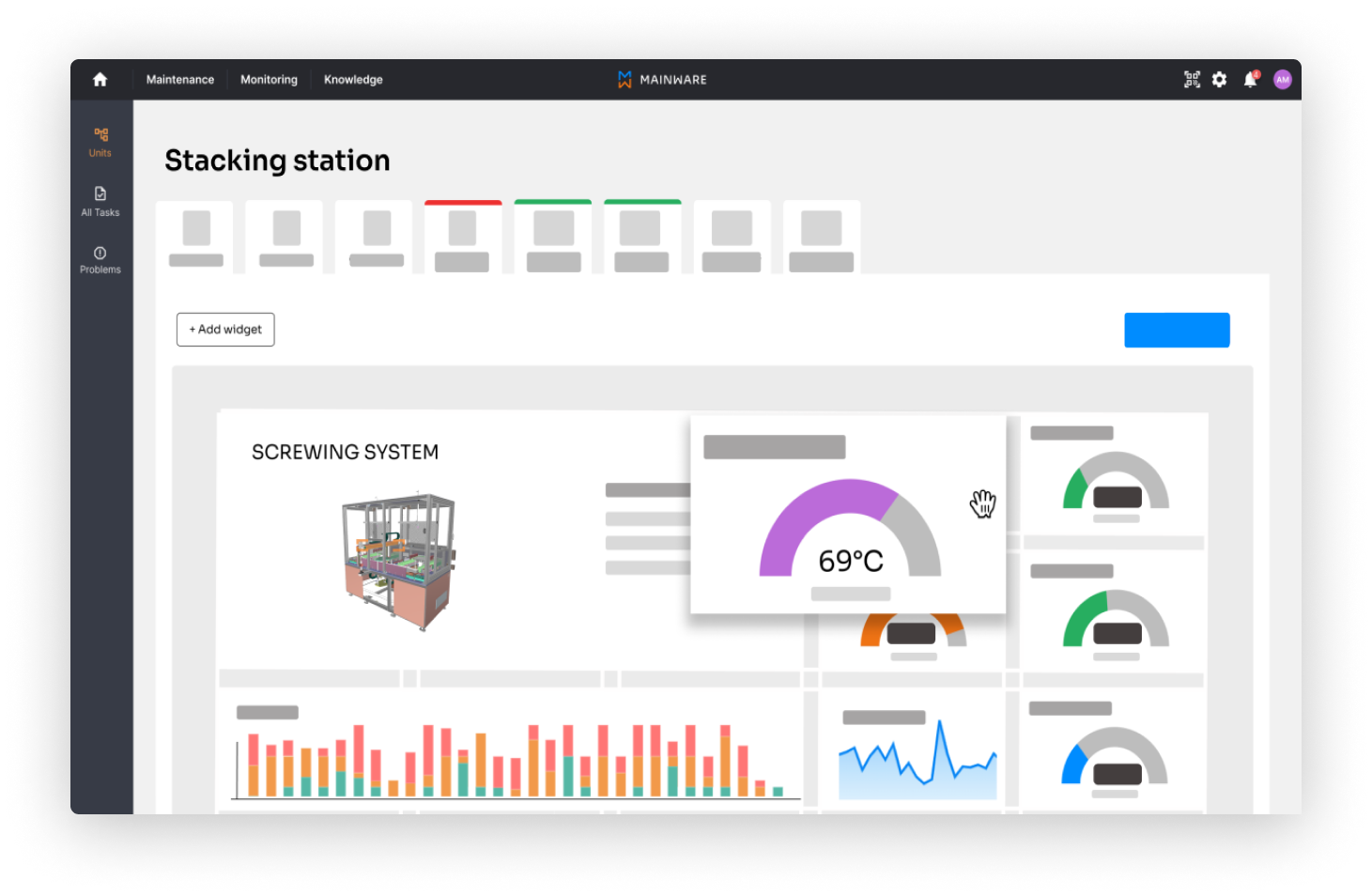

Machine overview

Create custom dashboards to monitor the machine. Analyse alarms, cycle times together with videos to increase machine’s output.

What will you get?

1️⃣ Web application

MAINWARE is a web application

which means you can access it from

any device over a web browser

anywhere around the world.

2️⃣ Scalable application.

Whether you manage one machine or

a whole fleet of them, MAINWARE is

prepared to keep up with your needs

as you scale up.

3️⃣ SaaS licensing.

Get all features of the platform

and only pay according to how

many machines you deliver to

your customers.

4️⃣ White labeled.

Deliver your machines with a

digital offering branded with

your company's logo to

empower your brand and image.